MW Preheating of Master Batch

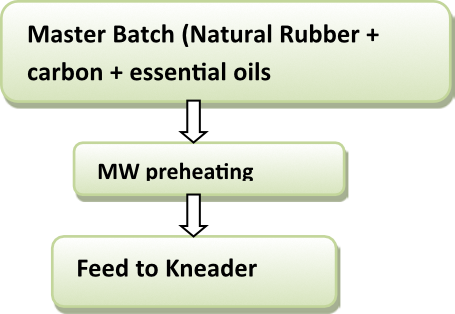

The master batch contains a mix of natural rubber, carbon and essential oils. Careful kneading and proper mixing of these elements decide the quality of the end product. In conventional methods, rubber manufacturers use a high temperature hot air ovens or do not heat the master batch before kneading.

With our MICROWAVE HEATING TECHNOLOGY, you can rule out the need for a large preheating ovens. Instead, the microwave preheater sits right before the kneader. This enablesyou to heat the master batch before it is ready to be dropped in the kneader without consuming a lot of power or time. Making your production faster and more efficient. (Mastication)

- The preheating takes minutes instead of hours/days as in conventional methods.

- Microwave heating ensures homogeneous temperature throughout the mass.

- Prevents overheating of the kneader by reducing the need for excess torque.

- Uniform mixing of every element for the final compounding batch.

Where does it fit in your chain?

Video

MW Preheating of Master Batch

| Application | Where To Implement | Advantages / USPs |

|---|---|---|

| MW preheating of Master Batch (Natural Rubber + carbon + essential oils) before Kneader |  |

|

*Trials & technical support for microwaveable compounding can be provided at our factory through our association for people who have interested.

| Standard Models : MW-preheating of NaturalRubber Bale / Master Batch Conveyerised | ||||

| Model No: | TW/MWPH/6K/CON | TW/MWPH/9K/CON | TW/MWPH/12K/CON | TW/MWPH/16K/CON |

| Production capacity kg /Hr. (approx.) | 80-100 kg/Hrs. | 120-140 kg/Hr. | 170-200 kg/Hr. | 240-260 kg/Hr. |

| Frequency | 2.45 GHz | |||

| Installed Microwave Power requirements | 6 KW | 9 KW | 12 KW | 16 KW |

| Installed electrical power | 9KWh | 14 KWh | 18KWh | 24 KWh |

| Belt width | 400 mm | 500 mm | 500 mm | 500 mm |

| Microwave Zone size in mm (Approx.) | 1800 x 560 x410 (L*W*H) | 2500 x 700 x410 (L*W*H) | 3000 x 700 x410 (L*W*H) | 4000 x 700 x410 (L*W*H) |

| Overall Dimension in mm (Approx.) | 3800 x 720 x 1400 (L*W*H) | 4500 x 720 x 1400 (L*W*H) | 5000 x 720 x 1400 (L*W*H) | 6000 x 720 x 1400 (L*W*H) |

| Preheating Time | 30 minutes | 30 minutes | 30 minutes | 30 minutes |

| Max Preheating temperature | 50° – 70 ̊ centigrade (adjustable) | |||

| MOC | Cavity SS 304/ support structure MS Powder coated | |||

Note : Customized Models for higher capacity are also can be made available on request.