Microwave Rubber Vulcanization

Microwave Rubber Vulcanization is one of the most effective applications for microwave heating. Methods relying on heating through conduction become inefficient due to the poor conductivity of rubber. However, with Microwave heating, the heat is generated from the core by homogeneously penetrating the rubber.

Our equipment allows the rubber to be heated to the right temperature while a flow of hot air at 240 °C{ Temp is adjustable according to compound} maintains the ideal conditions for vulcanization. Our equipment supports the process of continuous vulcanization/curing efficiently.

- The profile undergoing microwave heating results in faster, economical and uniform bonding due to higher molecular vibrations

- Pressure less curing of the polymer profile and thus high temperature is achieved without the need for high pressure

- Short cross-links impart better heat resistance for the rubber.

- The microwave acts quicker than conventional hot air heating and targets inner moisture content to achieve quick heating.

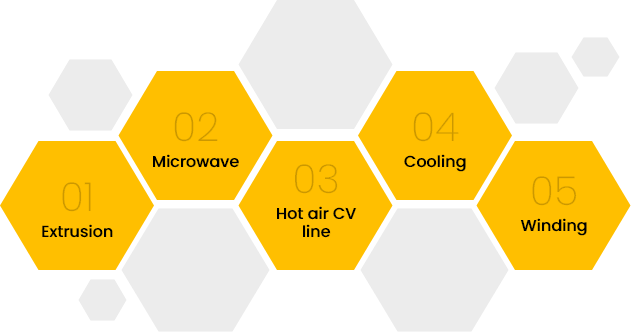

Where does it fit in your chain?

Videos

Microwave Rubber Vulcanization

Microwave Hot air continuous Vulcanization Systems

Let the technology work for you

Major tool for improving quality, productivity & reduction in production cost

“TWIN” Continuous Rubber Vulcanization system is specially designed for Rubber Extrusion Industries to carry out Continuous Vulcanization of Extruded Solid & Sponge Rubber Products. This is cost effective solution for Rubber Industries.

The technology is GREEN TECHNOLOGY. Saves fuel/electricity, time & also help to reduce environment pollutions.

Advantages & USP’s :

- Fast and even curing

- Clean and cost-effective process

- Reduce Energy Consumption

- Eliminating problems like over-curing

- Excellent Product Quality

- Saving valuable work floor space

- Green technology

Application : Continuous Rubber vulcanizing Rubbers can be cured :

| EPDM | Natural- NBR |

| Nitrile | White EPDM |

| Sponge Rubber |

Trials & technical support for microwaveable compounding can be provided at our factory through our association for people who are interested.

Safety Features :

- Microwave cavity is designed for Human safety. Required Interlocks incorporated

- Specially designed Microwave chokes for restricting Microwave radiations as per international standard of < 5mW/mm2

- Combination Models of Microwave & Hot air Line as per Production Requirement as below.

Standard Models :

| MODEL NOS | TW/11M/4500 | TW/17M/9000 | TW/23M/12000 | TW/29M/12000 |

| SPECIFICATIONS | ||||

| PRODUCTION CAPACITY ** | 75 TO 85 KG /HR | 125 TO 150 KG /HR | 150 TO 200 KG /HR | 200 TO 250 KG /HR |

| INCLUSION | A) MW +HOTAIR LINE – | A) MW +HOTAIR LINE -1 | A) MW +HOTAIR LINE -1 | A) MW +HOTAIR LINE -1 |

| B) Hot Air Unit – 0 | B) Hot Air Unit – 1 | B) Hot Air Unit – 2 | B) Hot Air Unit – 3 | |

| TOTAL DIMENSION (approx.) | 11 Mtr (L) X 1.10Mtr(W) X 1.450 Mtr(H) | 17 Mtr (L) X 1.10Mtr(W) X 1.450 Mtr(H) | 23 Mtr (L) X 1.10Mtr(W) X 1.450 Mtr(H) | 29 Mtr (L) X 1.10Mtr(W) X 1.450 Mtr(H) |

| VULCANIZING ZONE LENGTH | 8 Meter | 14 Meter | 20 Meter | 26 Meter |

| Installed Microwave power | 4.5KW | 9KW | 12KW | 12KW |

| Microwave power control | Pulsating + Variable | Pulsating + Variable | Pulsating + Variable | Pulsating + Variable |

| hot air power | 25KWH | 25 * 2 KWH | 25 * 3 KWH | 25 * 4 KWH |

| Total Installed Electrical Power | 35 KWH (47 HP) | 70 KWH (94 HP) | 100 KWH (134HP) | 125 KWH (167HP) |

| Belt width | 200mm | 200mm | 200mm | 200mm |

| belt height from ground. | 1150 mm | 1150 mm | 1150 mm | 1150 mm |

| VFD drive for speed | 0.5 mtr./min. to 16 mtr/min. | 0.5 mtr./min. to 16 mtr/min. | 0.5 mtr./min. to 16 mtr/min. | 0.5 mtr./min. to 16 mtr/min. |

| MOC | 1.cavity: -SS304 2. support structure: – MS painted | |||

| Circulating type hot air generator integrated | ||||

| Temperature controller on line (for product temperature optional) | ||||

| Emergency shut down | ||||

| Viewing Windo at one Place | ||||

Note : Customized Models for higher capacity are also can be made available on request.

Microwave Rubber Vulcanization Suppliers

Looking for microwave rubber vulcanization suppliers in in India, Bangladesh, Malaysia, Kuwait, Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Saudi Arabia and Egypt? Twin Engineers is a leading supplier of advanced microwave technology for the rubber industry. Our products are designed to increase production efficiency and improve product quality, making them the perfect solution for any rubber manufacturing facility.