Microwave Booster

Make the vulcanization process efficient by installing Microwave Booster fixed within the hot air continuous vulcanization line. It is an innovative concept where you can fit these and boost the existing process. It will significantly improve the curing time and also the mechanical properties of the rubber profile.

As the microwave heating process does not rely on surface heat transfer, the vulcanization process becomes more efficient. You can also use microwave heating as an additional system to quicken the heating process. A long duration of exposure to heat can harden the rubber and make it practically difficult to carry out further processes. Using a microwave booster reduces the need for prolonged exposure and also results in higher output units per time along with existing hot air vulcanization

- Reduces energy consumption by shortening the time.

- Eliminates the risk of over-curing and maintains the desired mechanical properties.

- Maximum processing temperature ranges from 100 to 250 °C.(Temperature can be adjustable according to compound)

- Better power control with a microcontroller module that lets you make precise changes to the processing conditions.

- Speed controllable conveying system for better control over the curing process.

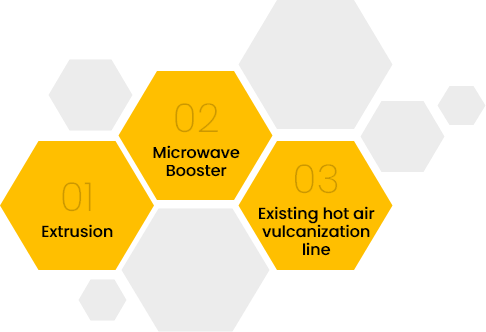

Where does it fit in your chain?

Videos

Microwave Booster

Microwave Booster Suppliers

Looking for a microwave booster suppliers in India, Bangladesh, Malaysia, Kuwait, Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Saudi Arabia and Egypt? If so, you came to the right place. For more information on our products and services, please contact our team of experts. We are dedicated to providing you with the best solution for your specific needs.